Kentucky-based processing company uses hemp to replace plastic and glass fibers

- Kentucky Hempsters

- Jun 27, 2016

- 2 min read

Updated: Jan 16, 2019

Can you imagine a kayak made of Kentucky hemp? How about your favorite coffee mug, or flowerpot? Better yet, your car? Thanks to a Louisville startup and its research and development through the Kentucky Hemp Pilot Program, it may not be long before that’s the case!

Kentucky-based hemp processor, Sunstrand, is turning Kentucky’s hemp crop into sustainable, high-quality replacements for plastic and glass fibers. The company contracts with Kentucky farmers to grow hemp, along with other natural fibers like Kenaf, to process and coat the natural fibers and re-sell to manufacturing buyers looking for replacements to synthetic materials.

Dr. Trey Riddle, a native of Louisville, launched Sunstrand after the passing of the Agricultural Act of 2014 (Farm Bill), which allowed hemp research to take place within the state. The company was formed to meet the needs of the emerging industry by providing biomaterials and processing services.

Sunstrand is now operating the United States’ first and only commercial industrial hemp decortication facility. In its pilot scale, the line has a processing capacity of 6 million pounds per year and is experimenting with a number of fiber inputs and outputs. Manufacturer’s buy these materials and make them into pellets with the ability to replace more expensive or less-sustainable plastics and glass fibers.

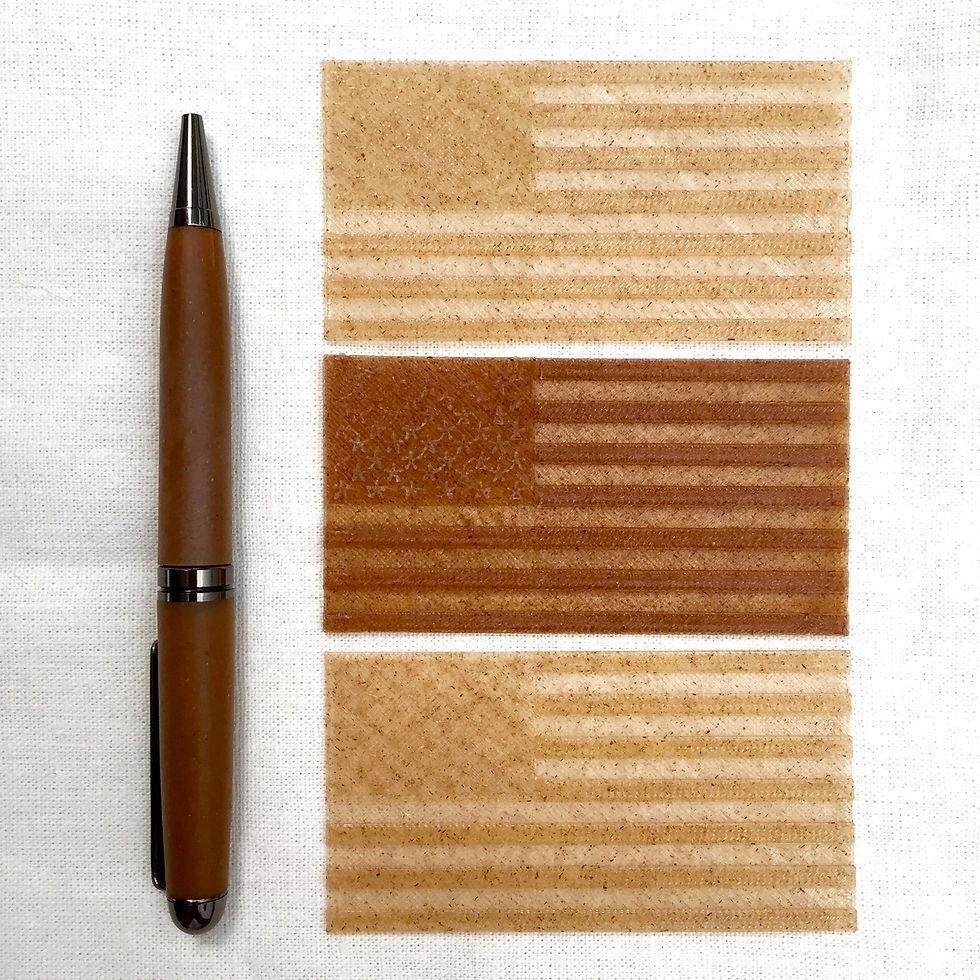

Currently the fibers are being used to experiment with furnace filters and filaments for 3D printing. Check out some of these 3D printed hemp prototypes from Green Spring Technologies below! Green Spring Technologies is based out of Fort Worth Texas, and made these hemp plastic flags and pens using Kentucky hemp processed by Sunstrand.

This month, the company was awarded a $150,000 research grants to further its research and development. Now Sunstrand is evaluating a novel line of natural fiber mats for acoustic and thermal applications. Riddle claims the company’s natural fibers are expected to improve noise absorption properties, while reducing costs over several current product lines. In addition, the grant money will be used to explore Sunstrand’s materials in automotive, appliance, building materials and other sectors. For more information about Sunstrand visit www.sunstrands.com.

---

Sources

http://www.courier-journal.com/story/money/companies/2016/04/12/engineers-startup-weaves-hemp-natural-fibers/82741304/

http://www.sunstrands.com/sunstrand-operating-commercial-hemp-decortication-facility-us/

http://www.sunstrands.com/sunstrand-awarded-150000-research-grant/

http://www.sunstrands.com/sunstrand-founder-kyhia-president-speak-hemp-conference/

https://www.youtube.com/watch?v=YwKfXTw1o_E

Comments